Offer

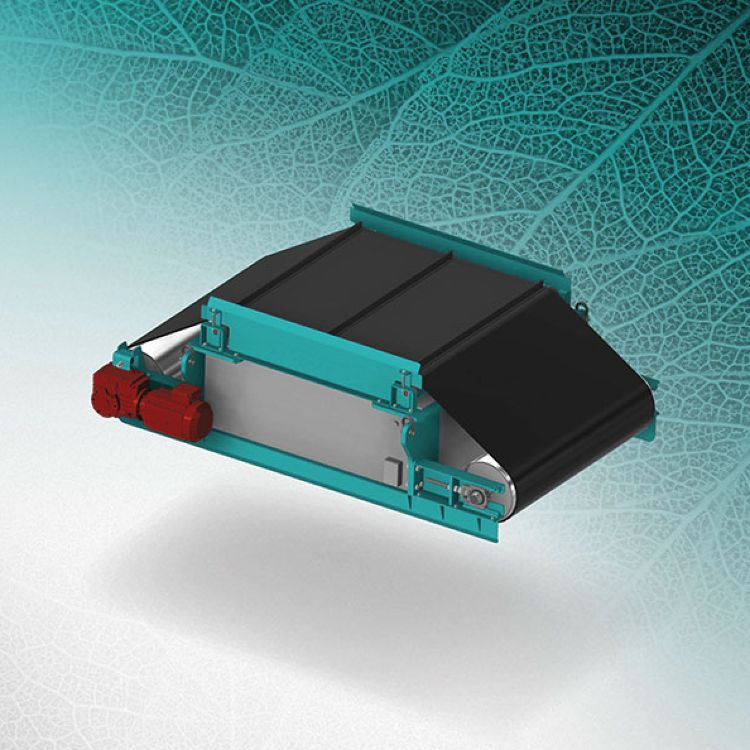

Electromagnetic separator SEM

The separator is used to recover metals from all types of waste. It is designed to be installed at municipal, industrial and post-construction waste sorting lines.

Electromagnetic separator is dynamic system designed to collect and separate ferromagnetic materials from input material (fraction) transported on belt conveyor. The principle of device’s operation is to place certain working area of belt conveyor under intensive magnetic field generated by electromagnet block. As result, steel materials transported on conveyor belt are captured (collected) in middle area of electromagnetic separator and moved by separator’s belt towards its end, where magnetic field generated by electromagnet is lower. When magnetic attraction disappears, steel material automatically falls on other conveyor or into the container.

| TECHNICAL CHARACTERISTICS | ||

| Type | SEM 120 - 140 | SEM 140 - 160 |

| Size of electromagnet block [mm] | length 1250; width 1250; height 495 | length 1660; width 1360; height 505 |

| Total electromagnet’s power demand [kW] | 6.1 | 8 |

| Power of belt’s drive responsiblefor collection of captured elements [kW] | 3 | 4 |

| Total weight of device [kg] | ~3100 | ~3100 |

| Maximum suspension height of separator above belt [mm] | up to 390 | up to 560 |

| Install option: LONGITUDINALLY | over the chute, parallel to the direction of the conveyor belt run (configuration recommended for conveyors of max. belt width B = 1200 mm) | over the chute, parallel to the direction of the conveyor belt run (configuration recommended for conveyors of max. belt width B = 1400 mm) |

| Install option: TRANSVERSELY | over conveyor belt route, perpendicular to the direction of the conveyor belt run, or in the same way above conveyor’s chute (configuration recommended for conveyors of max. belt width B = 1400 mm) | over conveyor belt route, perpendicular to the direction of the conveyor belt run, or in the same way above conveyor’s chute (configuration recommended for conveyors of max. belt width B = 1600 mm) |